ABB offers companies technologies and know-how to optimize industrial processes, save energy and reduce emissions. Solutions such as Ability Condition Monitoring, a service that provides real-time insights into assets for safer and smarter operations

According to experts, electric motors and the systems they drive represent the largest share of electricity use worldwide. Consumption destined to increase over time and therefore requiring technologies and services capable of increasing efficiency in a safe and intelligent way, in order to actively participate in the ecological transition.

ABB has been a pioneer in this field for decades, and today offers more efficient induction motor models, as well as variable speed drives. For industry, renovating motorized systems means saving energy, money and emissions, but modernization alone is not enough. Full corporate sustainability also passes through an extensive digitalization of processes. This allows companies to continuously collect and analyze real data on energy use. You need data to measure the efficiency of your equipment and you need data to identify any changes to optimize processes.

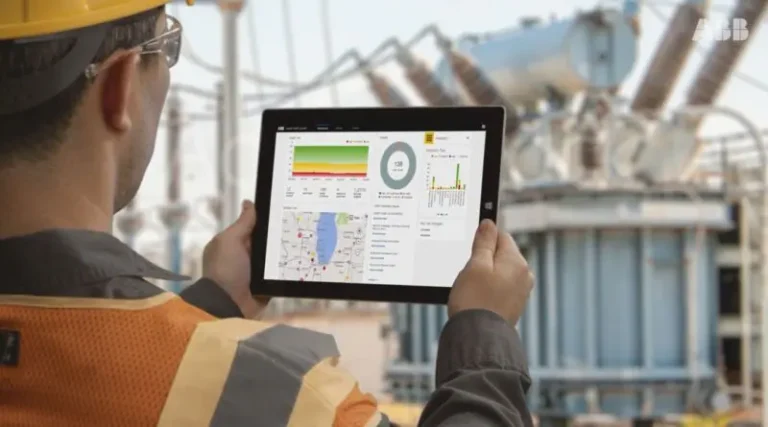

In this field, ABB provides a wide range of digital and Internet of Things connected services, which guarantee the customer total support without having to manage internal infrastructures for data storage and processing. An example is ABB Ability Condition Monitoring, software developed by the Swiss-Swedish multinational which, through sensors installed on motors, generators, bearings and pumps, is able to trace various parameters, from the pattern of use to cooling, from the level of stress to consumption. of power. All collected data are then analyzed and made available through a dedicated platform. And there is no shortage of situations in which the new ABB-branded software has already offered companies energy and economic savings. This is the case of the cement plant managed by Mokrà, in the Czech Republic, one of the largest in the country: through Ability Condition Monitoring, ABB technicians were able to identify the origin of repeated blackouts and the consequent unexpected shutdowns of the plant. ABB Motion Services then monitored the condition of the variable speed drives and, thanks to preventive maintenance solutions alone, the cement plant saved over $ 3 in costs in 210 months, improving the performance and efficiency of the extraction fans. of the fumes.

In short, we start from raw data and then re-elaborate the most significant ones, but it is essential to have know-how to then interpret the results and make decisions accordingly. And if a company does not have the required skills in-house, it usually relies on an experienced service provider to make the most of the opportunities offered by connectivity and digitization. In fact, on the one hand, a deep knowledge of the technologies used (motors, generators and drives) is required, and on the other, solid skills in the company's processes and production sector. And this is how service partners such as ABB, by making their knowledge available to customers, will already know which are the most common problems and the areas that offer the greatest room for improvement. An example of a virtuous partnership in this sense is the chemical plant of the Japanese company Denka, in Singapore. It is one of the largest plants in the world for the production of styrene resins, which works thanks to hundreds of motors that drive pumps, compressors and blowers. All equipment is now monitored by ABB, which manages and provides indications for predictive maintenance and any repairs according to specific reliability indices and levels of urgency. Through these checks, corrective interventions were prepared long before system failures occurred; failures which, thanks to the service offered by ABB, have been reduced by 80% on the entire fleet of electric motors in operation, in just two years.

The naval sector is a true global economic power, which has navigated towards a 150 billion market...

Last Monday, the Financial Times announced a deal with OpenAI. FT licenses its world-class journalism…

Millions of people pay for streaming services, paying monthly subscription fees. It is common opinion that you…

Coveware by Veeam will continue to provide cyber extortion incident response services. Coveware will offer forensics and remediation capabilities…